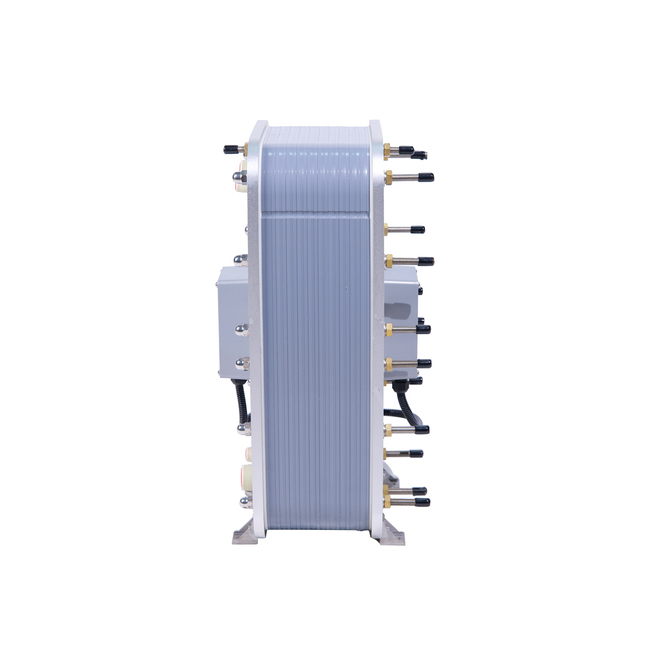

HM-EDI-5

Product Line Description

4.5 to 5.5 Cubic Meter Per Hour (m³/h) Product Flow Electrodeionization (EDI) Module for Water Polishing.

Electrodeionization is currently the most advanced technology for ion-exchange. With this technology (ultra)pure water can be produced continuously. This high-end technology can have an application in sectors such as: Power plants, process industry and pharmaceutical industry. An EDI-unit is usually used as a post treatment of Reverse Osmosis water.

| Specifications | |

|---|---|

| Brands | HUAMO JMCC |

| Product Flow | 4.5 to 5.5 m³/h |

| Recovery | 90 to 95 % |

| Resistivity | ≥ 15 MΩ·cm |

| Direct Current Voltage (DCV) | 80 to 300 V |

| Direct Current Amperage (DCA) | 2 to 5 A |

| Inlet Pressure | 0.15 to 0.4 MPa |

| Maximum Pressure | 0.7 MPa |

| Fresh Water/Water Pipe Nozzle Size | DN25 |

| Fresh Water Inlet/Outlet Nozzle Size | DN15 |

| Requested of Feed Water | |

| Resource Water | RO water conductivity less than 20 µS·cm better than 10 µS·cm |

| Potential of Hydrogen (pH) Range | 6.0 to 9.0 pH |

| Temperature Range | 5 to 35 ºC |

| Hardness | < 0.5 ppm |

| Maximum Organics | 0.5 ppm |

| Recommended Organics | 0 ppm |

| Maximum Oxidizers | 0.05 ppm |

| Maximum Iron-Manganese (Fe-Mn) | 0.01 ppm |

| Maximum Silica | 0.5 ppm |

| Maximum Carbon Dioxide | 5 ppm |

| Oil | Not Detectable |

| Additional Information | |

| Electrodeionization (EDI) is an electrically-driven water treatment technology that uses electricity, ion exchange membranes and resin to remove ionized species from water.

It is wisely combined electro dialysis with ion exchange technology, by using of high-voltage electrodes at both ends to drive charged ion in the water to move, and with the ion exchange resin and selective resin membrane to accelerate ions moving, so as to achieve the purpose of water purification. |

|