Hydrophobic Polytetrafluoroethylene (PTFE) Pleated Filter Cartridges

Product Line Description

PTFE Pleated Filter Cartridge is constructed of PTFE media and non-woven support materials. This kind of pleated filter cartridge is absolutely rate and in hydrophobic condition. It possess low pressure drop and high flow rates. The extensive applicability enable filter cartridge to be high strength, long service life and cost-effective.

| Specifications | |

|---|---|

| Brands | JMCC |

| Material of Construction | |

| Filter Media | Hydrophobic Polytetrafluoroethylene (PTFE) |

| Support Layer | Polypropylene (PP) |

| Core/Cage/End Adapter | Polypropylene (PP) |

| Sealing Method | Thermal Bonding No Adhesives |

| Filtration Area Per 10 Inch (in) Length | 0.64 m² |

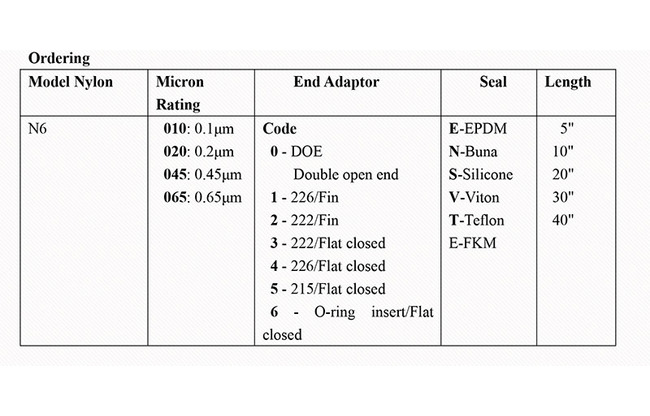

| Ordering Information | |

| Model | PTFE-HB |

| Micron Rating | 010 – 0.1 µm 020 – 0.2 µm 045 – 0.45 µm |

| End Adapter | 0 – DOE (Double Open End) 1 – 226/Fin 2 – 222/Fin 3 – 222/Flat Closed 4 – 226/Flat Closed 5 – 215/Flat Closed 6 – O-Ring Insert/Flat Closed |

| Seal Materials | E – Encapsulated Fluorocarbon (E-FKM) E – Ethylene Propylene Diene Monomer (EPDM) N – Buna S – Silicone T – Polytetrafluoroethylene (PTFE) V – Fluorocarbon (FKM) |

| Dimensions | |

| Length | 5 – 5 in. 10 – 10 in. 20 – 20 in. 30 – 30 in. 40 – 40 in. |

| Outside Diameter | 2.7 in 69 mm |

| Recommended Operating Conditions | |

| Forward Pressure at 25 Degree Celsius (ºC) Temperature | 4.2 bar |

| Reverse Pressure at 25 Degree Celsius (ºC) Temperature | 2.0 bar |

| Maximum Operating Temperature | 95 ºC |

| Sterilization Temperature | 121 ºC |

| Sterilization Time Per Cycle | 30 min |

| Number of Sterilization Cycles | 100 |

| Integrity Test | |

| 100 Percent (%) Isopropyl Alcohol (IPA) Bubble Point Pressure for 0.1 Micrometer (µm) Pore Size | 1.5 bar |

| 100 Percent (%) Isopropyl Alcohol (IPA) Bubble Point Pressure for 0.2 Micrometer (µm) Pore Size | 1.0 bar |

| 100 Percent (%) Isopropyl Alcohol (IPA) Bubble Point Pressure for 0.45 Micrometer (µm) Pore Size | 0.6 bar |

| Applications | |

|

|

| Additional Information | |

| Having a particulate removal rating of 0.1 µm for gas and microorganisms of 0.2 µm for liquids. 100% integrity tested by bubble point and diffusional flow to ensure consistent and reliable performance. Oxidation-resistant materials of construction for such filter cartridge. No adhesive, thermal bonded manufacturing without adhesives. | |