Hydrophobic Polyvinylidene Fluoride (PVDF) Pleated Filter Cartridges

Product Line Description

PVDF Pleated Filter Cartridge is constructed of PVDF media and non-woven support materials. This kind of pleated cartridge filter with absolutely rate and in hydrophobic condition for great throughput and pp components for broad chemical compatibility. The compatibility with a broad range of chemicals provides long service life.

| Specifications | |

|---|---|

| Brands | JMCC |

| Material of Construction | |

| Filter Media | Hydrophobic Polyvinylidene Fluoride (PVDF) |

| Support | Polypropylene (PP) |

| Core/Cage/End Adapter | Polypropylene (PP) |

| Sealing Method | Thermal Bonding No Adhesives |

| Filtration Area Per 10 Inch (in) Length | 0.64 m² |

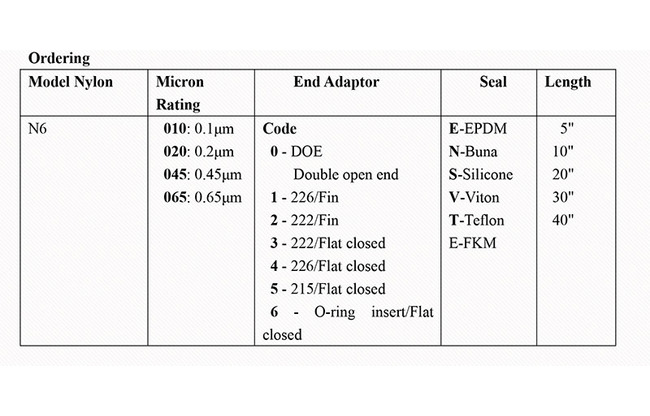

| Ordering Information | |

| Model | PVDF – Polyvinylidene Fluoride (PVDF) |

| Micron Rating | 010 – 0.1 µm 020 – 0.2 µm 045 – 0.45 µm |

| End Adapter | 0 – DOE (Double Open End) 1 – 226/Fin 2 – 222/Fin 3 – 222/Flat Closed 4 – 226/Flat Closed |

| Seal Materials | E – Encapsulated Fluorocarbon (E-FKM) E – Ethylene Propylene Diene Monomer (EPDM) N – Buna S – Silicone T – Polytetrafluoroethylene (PTFE) V – Fluorocarbon (FKM) |

| Dimensions | |

| Length | 5 – 5 in. 10 – 10 in. 20 – 20 in. 30 – 30 in. 40 – 40 in. |

| Outside Diameter | 2.7 in 69 mm |

| Recommended Operating Conditions | |

| Forward Pressure at 25 Degree Celsius (ºC) Temperature | 4.2 bar |

| Reverse Pressure at 25 Degree Celsius (ºC) Temperature | 2.0 bar |

| Maximum Operating Temperature | 90 ºC |

| Sterilization Temperature | 121 ºC |

| Sterilization Time Per Cycle | 30 min |

| Number of Sterilization Cycles | 100 |

| Applications | |

|

|